It’s Sunday night. There are just a couple more hours left before I go to sleep and my second week at ESA begins… In spite of it being nearly 10:00pm, the sun is still above the horizon shredding gold through the clouds here and there, and even making this killer rainbow chunk.

Last Sunday, I arrived in Holland. It felt like I was tied to an unstoppable force being propelled through uncertainty towards a heap of even more unknowns… which was exciting or terrifying or equal parts both. Once I made it safely to the *penthouse* I’ve been taking roost in (its on the top floor of the tallest building around, at 3 stories. perfect nest), I began mentally preparing myself for what was to come.

Last Sunday, I arrived in Holland. It felt like I was tied to an unstoppable force being propelled through uncertainty towards a heap of even more unknowns… which was exciting or terrifying or equal parts both. Once I made it safely to the *penthouse* I’ve been taking roost in (its on the top floor of the tallest building around, at 3 stories. perfect nest), I began mentally preparing myself for what was to come.

During the four days of my first week at ESA, I’ve had a good share of wonderful conversations with people who have had many inspiring life experiences and knowledge in areas that until now, I’ve known very little about. I’ve been getting acquainted and have been compiling my environment. I can now walk down the hallways of the building I call home-base and wave to most of the people now because there is some level of familiarity.

I feel kind-of like Annie arriving at Daddy Warbuck’s mansion. I’ve sat with a different crowd every day for lunch, had tea and coffee with those who were willing to share a few moments with me, and wandered around with aw-filled doe eyes while absorbing the initial pleasure shock of being in a new environment that has until now been merely an abstraction in my imagination.

Defining the Meaning in my Absurdity

Equally important as what I hear from the brilliant minds available to me, is what I end up saying to them about myself. With every conversation I start with each new person I meet, I’m in a position where I need to verbally illustrate what it is that I do and why. I actually get to hear myself explain Noodle, who he is and what his existence is all about. In the moment, my brain has to chisel out the words and commit to them.

The elevator pitch is a difficult thing to hone. Not only is the concept broad, much of the meaning beneath my work is an abstract “where my head is” sort of thing that’s the result of my life experiences leading up to now (and where I am in the moment). I can feel what my work means to me, but I’m not often needing to describe where the river started, or where I presume it’s going.

Since I obviously haven’t been working on prototypes, or CAD, or anything physical like I typically do, I’ve allowed myself to really think about all that philosophy hoo-ha that everyone hates artists for getting so “overly” gushy about (bats eyes).

It’s important to draw inward and exhale… and I’ve come to realize that’s what this journey is about. Instead of tirelessly pushing my face into the design- I must listen to others, observe the interaction and then meditate on the sparks that few off in the process.

Anyhow… I’m enjoying every minute of it ❤ I finished off my week by taking Noodle to the beach near our nest for his first big sand. He got to pretend he’s a strand beast =D

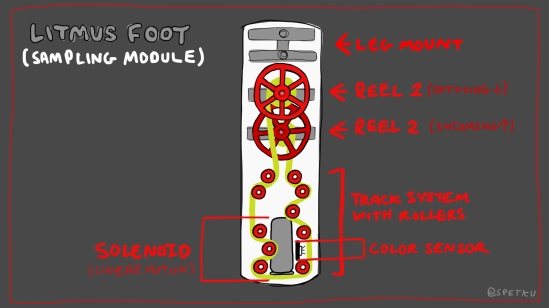

After admitting that my creations didn’t actually do what I enjoyed bragging about, there was some talk about how I could simulate the act of ‘tasting’ more effectively. Almost immediately, the idea of using litmus paper came up, and I think it has sat on the immediate back burner of my mind ever since.

After admitting that my creations didn’t actually do what I enjoyed bragging about, there was some talk about how I could simulate the act of ‘tasting’ more effectively. Almost immediately, the idea of using litmus paper came up, and I think it has sat on the immediate back burner of my mind ever since. This past week… I finally made what I can comfortably call, Noodle’s first tasting foot appendage… *cheers*

This past week… I finally made what I can comfortably call, Noodle’s first tasting foot appendage… *cheers* HOW IT WORKS

HOW IT WORKS (See video @ top for a more detailed explanation)

(See video @ top for a more detailed explanation) To make my point… Last month I got a bag of Jelly Beans to use while developing my bean planting module. I measured the dimensions of a small handful as references for the thing I was designing, but the rest of course, got eaten.

To make my point… Last month I got a bag of Jelly Beans to use while developing my bean planting module. I measured the dimensions of a small handful as references for the thing I was designing, but the rest of course, got eaten. From now until the end of August, my goal is to produce four different tasting modules that each demonstrate some aspect of sampling or preference. You could think of them as the “four tasters of the apocalypse”…

From now until the end of August, my goal is to produce four different tasting modules that each demonstrate some aspect of sampling or preference. You could think of them as the “four tasters of the apocalypse”…

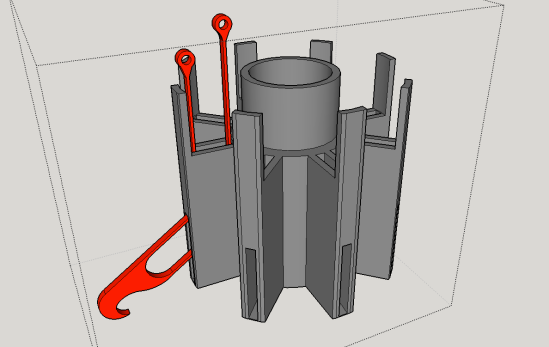

This module will execute three different tasks in one planting cycle: CORING, DISPENSING, and WATERING

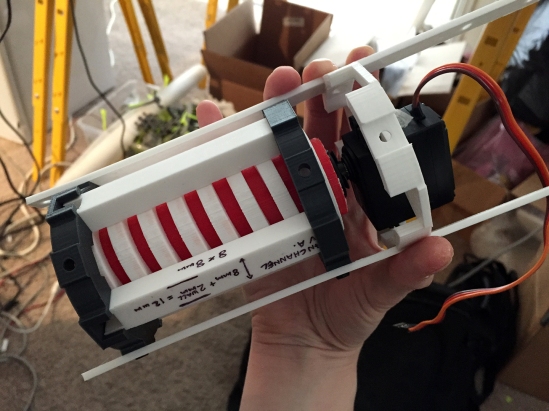

This module will execute three different tasks in one planting cycle: CORING, DISPENSING, and WATERING My candy cane hopper shape captures the beans in-between the threads and processes them upwards within channels that flank the spiral:

My candy cane hopper shape captures the beans in-between the threads and processes them upwards within channels that flank the spiral: Once fully loaded, every time the helix rotates 90 degrees, it will carry one bean to the exit slot on the inside wall at the top. The bean will then drop down the hollow center of the helix and into the coring device below… (which… is next on my list to design)

Once fully loaded, every time the helix rotates 90 degrees, it will carry one bean to the exit slot on the inside wall at the top. The bean will then drop down the hollow center of the helix and into the coring device below… (which… is next on my list to design) This is the first assembly I’ve ever designed in Fusion360. One week into using it, I’m sad I didn’t make the switch sooner!!! If you’re considering doing so too, bite it and take the leap! Your life will be so much better once you do!

This is the first assembly I’ve ever designed in Fusion360. One week into using it, I’m sad I didn’t make the switch sooner!!! If you’re considering doing so too, bite it and take the leap! Your life will be so much better once you do!

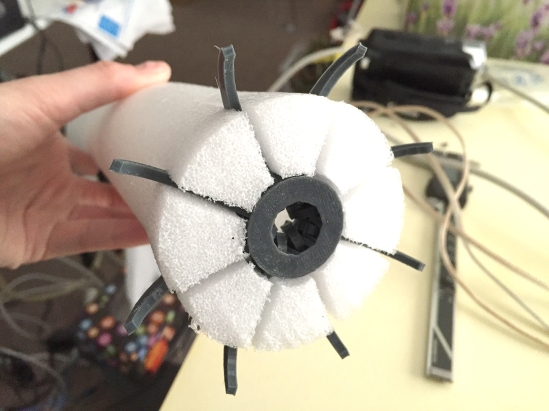

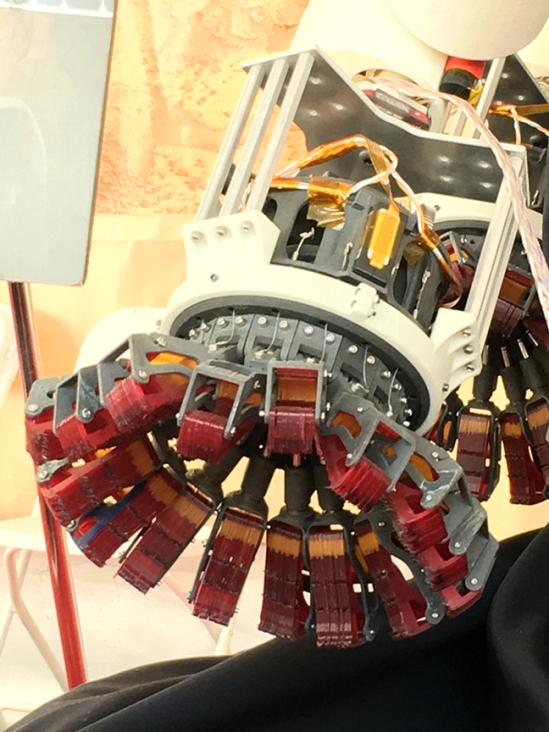

In order to attach that density of toe tendons to the toe-ring, I had to eliminate the use of hardware (which was kind of a relief). As improvisation, I threaded some 3mm rubber hose through the loops of the toe tendons to hold everything in place.

In order to attach that density of toe tendons to the toe-ring, I had to eliminate the use of hardware (which was kind of a relief). As improvisation, I threaded some 3mm rubber hose through the loops of the toe tendons to hold everything in place. With one complete proof-of-concept to show, I set everything down and allowed myself to become very distracted with a whole slew of things (which is good). My life exploded momentarily and when everything settled back down about a month ago, I found myself looking at an opportunity to travel to Linz, Austria to exhibit something of mine at the ARS Electronica festival [!]

With one complete proof-of-concept to show, I set everything down and allowed myself to become very distracted with a whole slew of things (which is good). My life exploded momentarily and when everything settled back down about a month ago, I found myself looking at an opportunity to travel to Linz, Austria to exhibit something of mine at the ARS Electronica festival [!] I’m grateful I had Mark and Tony to help wherever I needed aide picking up the slack. One glass of wine at a time, and one task after another, the new feet took shape and were installed on Noodle (mere hours before I would need to disassemble him completely for his long flight over to Linz in my suitcase).

I’m grateful I had Mark and Tony to help wherever I needed aide picking up the slack. One glass of wine at a time, and one task after another, the new feet took shape and were installed on Noodle (mere hours before I would need to disassemble him completely for his long flight over to Linz in my suitcase).

During this gauntlet he held his own, but Noodle did blow out a servo motor. Just as I was returning to my exhibit area to check in on Mark (who would periodically drop by to watch over the young one while I was away), I saw a nice white plume of smoke streaming forth from Noodle’s foot. Apparently they can’t quite handle hours of continuous use- so the toes are just that chafey.

During this gauntlet he held his own, but Noodle did blow out a servo motor. Just as I was returning to my exhibit area to check in on Mark (who would periodically drop by to watch over the young one while I was away), I saw a nice white plume of smoke streaming forth from Noodle’s foot. Apparently they can’t quite handle hours of continuous use- so the toes are just that chafey. Like his name suggests, Noodle is a “feet-based” mechanical life form who has been designed to taste objects (among many other things). Though Noodle has lofty aspirations for world domination, he is still a fledgling one-year-old… and his mommy (me) needs to work on equipping him with all the space exploration and world conquering super goodies he’ll need while on his journey. For that, he is in a state of perpetual growth.

Like his name suggests, Noodle is a “feet-based” mechanical life form who has been designed to taste objects (among many other things). Though Noodle has lofty aspirations for world domination, he is still a fledgling one-year-old… and his mommy (me) needs to work on equipping him with all the space exploration and world conquering super goodies he’ll need while on his journey. For that, he is in a state of perpetual growth. OK, SO… A LITTLE LICKING, AND THE PROSPECT OF DROOL… BUT FIRST GRIPPING:

OK, SO… A LITTLE LICKING, AND THE PROSPECT OF DROOL… BUT FIRST GRIPPING: About a year ago last Fall, I stumbled upon a video of

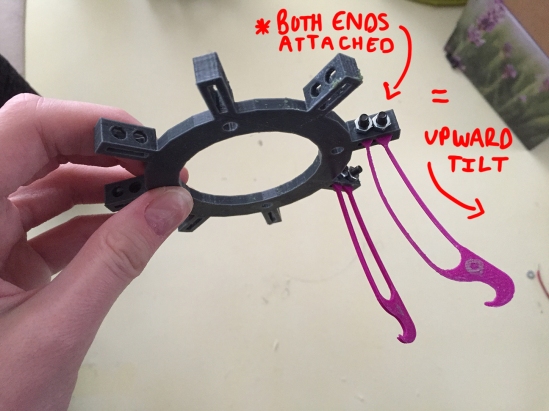

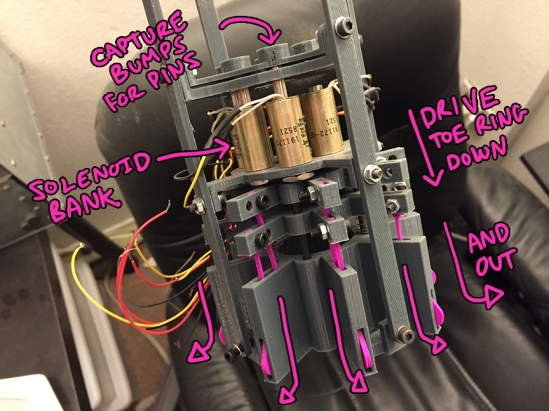

About a year ago last Fall, I stumbled upon a video of  The ring would need to be driven downward in order to force the toes through individual channels and out from slot-like sheaths. Finding a *good* way to drive the toes downward would become a bit of a challenge for me…

The ring would need to be driven downward in order to force the toes through individual channels and out from slot-like sheaths. Finding a *good* way to drive the toes downward would become a bit of a challenge for me… I did a lot of design and printing, only to realized the solenoids are in fact pretty weak, and not ever going to have the ability to press against the force of my springs; at least not ones as small as I would need in order to fit in Noodle’s feet:

I did a lot of design and printing, only to realized the solenoids are in fact pretty weak, and not ever going to have the ability to press against the force of my springs; at least not ones as small as I would need in order to fit in Noodle’s feet: The tongue piece is a silicone brush that I bought from Ali-Express China. It is some sort of baster that was originally attached to a squeezable bladder. The brush end is removable and has a single pore in the center for excreting fluid. PERFECT for when I add the salivating feature later on:

The tongue piece is a silicone brush that I bought from Ali-Express China. It is some sort of baster that was originally attached to a squeezable bladder. The brush end is removable and has a single pore in the center for excreting fluid. PERFECT for when I add the salivating feature later on: I tried for a day or so to come up with a rack and pinion system to push a spring tensioned tongue out the bottom of Noodle’s foot. Though it worked, it had a tendency to bind and wasn’t as reliable as I’d need it to be.

I tried for a day or so to come up with a rack and pinion system to push a spring tensioned tongue out the bottom of Noodle’s foot. Though it worked, it had a tendency to bind and wasn’t as reliable as I’d need it to be.

If you enjoy the content on this blog and would like to see more of it… A LOT MORE of it, then consider checking out

If you enjoy the content on this blog and would like to see more of it… A LOT MORE of it, then consider checking out  Carl’s fate is to become a ball-balancing robot… one with motors and wheels… that can balance… on a ball. If you’ve ever seen one,

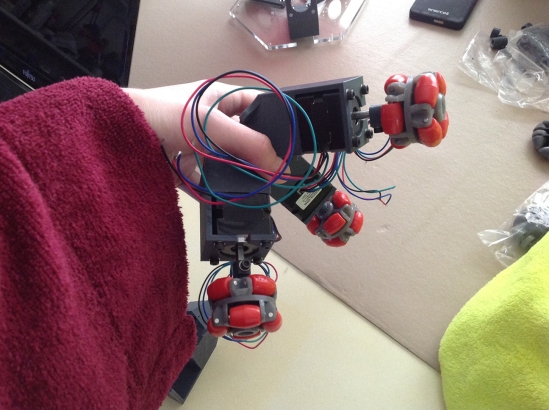

Carl’s fate is to become a ball-balancing robot… one with motors and wheels… that can balance… on a ball. If you’ve ever seen one,  So, they’re wheels with wheels. heh. They’re needed so the ball can glide freely in whatever direction the motors collectively force it to… like butter. Friction is bad. Binding is bad.

So, they’re wheels with wheels. heh. They’re needed so the ball can glide freely in whatever direction the motors collectively force it to… like butter. Friction is bad. Binding is bad. Almost immediately after putting together this first base assembly, I drew what I thought I’d want the finished robot to look like… and saw in my own sketch that the assembly could be a lot more “talon-like” if the mounts of the motors branched out at 45 degree angles from a central point (instead of just being stuck to a big plate).

Almost immediately after putting together this first base assembly, I drew what I thought I’d want the finished robot to look like… and saw in my own sketch that the assembly could be a lot more “talon-like” if the mounts of the motors branched out at 45 degree angles from a central point (instead of just being stuck to a big plate). By this time my omni wheels had arrived, so my next challenge was to figure out how to mount them to the gear shaft of the steppers. Sadly, the wheels came with no couplers of any sort, so I would have to print my own. =[

By this time my omni wheels had arrived, so my next challenge was to figure out how to mount them to the gear shaft of the steppers. Sadly, the wheels came with no couplers of any sort, so I would have to print my own. =[ This coupler took me fourteen- YES ( 14 ) ! revisions to get the tolerances juuuuuusssst right… the shaft inside the wheel fits tight but not too tight:

This coupler took me fourteen- YES ( 14 ) ! revisions to get the tolerances juuuuuusssst right… the shaft inside the wheel fits tight but not too tight: With the wheels mounted to the steppers, the assembly looks kind like a big chicken foot:

With the wheels mounted to the steppers, the assembly looks kind like a big chicken foot: …which is what I wanted… BOCK!

…which is what I wanted… BOCK! At some point Thursday night… I pulled Carl from his metal legs and did the morbid task of marking his belly with a dotted line. Instead of doing the messy deed of severing his drum-sticks immediately, I got distracted and went to bed, leaving Carl nestled in Noodle’s blankie to suffer over night with thoughts of what would happen to him the following day.

At some point Thursday night… I pulled Carl from his metal legs and did the morbid task of marking his belly with a dotted line. Instead of doing the messy deed of severing his drum-sticks immediately, I got distracted and went to bed, leaving Carl nestled in Noodle’s blankie to suffer over night with thoughts of what would happen to him the following day. Cutting the big oval around his little birdy nubs wasn’t at all hard… Once I drilled a starter hole, the thin blown plastic cut like paper with a pair of nippers. When I finished, I held Carl and told him everything was going to be alright…

Cutting the big oval around his little birdy nubs wasn’t at all hard… Once I drilled a starter hole, the thin blown plastic cut like paper with a pair of nippers. When I finished, I held Carl and told him everything was going to be alright…

The screws that connected this fancy shape to Carl, went through his belly and met a plate of nuts set on the inside, clamping everything firmly in place (but this wasn’t easy to execute!):

The screws that connected this fancy shape to Carl, went through his belly and met a plate of nuts set on the inside, clamping everything firmly in place (but this wasn’t easy to execute!): There wasn’t anything to hold the plate on the inside of his body while I screwed into it… other than some tape, which kept coming loose and plopping down into the cavity of Carl… forcing me to start the process over again.

There wasn’t anything to hold the plate on the inside of his body while I screwed into it… other than some tape, which kept coming loose and plopping down into the cavity of Carl… forcing me to start the process over again. On the opposite end of the pipe, I made another adaptor that connected to the motor assembly:

On the opposite end of the pipe, I made another adaptor that connected to the motor assembly: Once this was added, I put everything together and had this sexy looking bird before me. The essence of the flamingo:

Once this was added, I put everything together and had this sexy looking bird before me. The essence of the flamingo: